Equipment

Technical Infrastructure and Equipment

Electrochemical Equipment

- Various potentiostats for potentiodynamic and potenitostatic EC (Autolab, Bio-logic, Gamry, Jaissle, Solartron, Zennium,…)

- Fast-response & high-frequency pulse potentiostats

- Bipotentiostatic measurements (Autolab)

- Low- and ultra-low current setups for electrochemical single nanoparticle analysis (npi, Elements)

- High current / high potential potentiostats

- Software

- Comsol – finite elements simulations

- DigiElch

- ORCA – DFT simulations

- Electrochemical Quartz Crystal microbalance

- Rotating disc setups (Glassy carbon and Pt electrodes)

- Electrochemical impedance spectroscopy

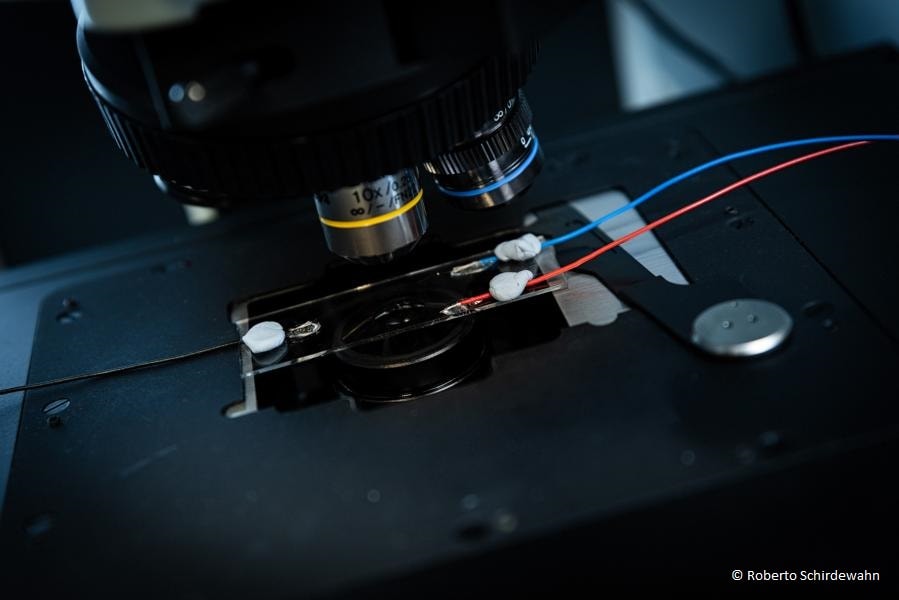

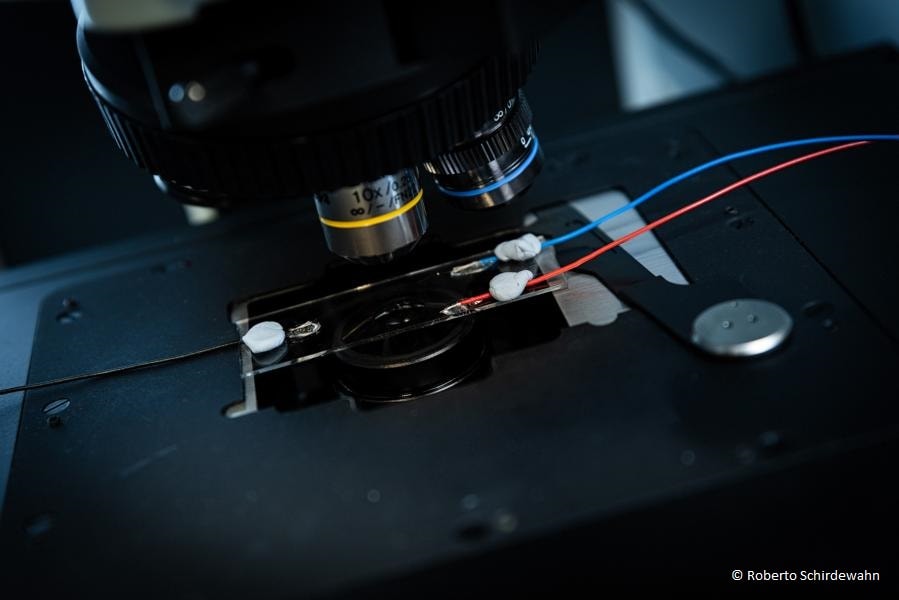

- Scanning Electrochemical Cell Microscope (probes with microscopic fingerprint)

- Scanning Ion Microscopy

- Scanning Electrochemical Microscope (Au and Pt microelectrodes, 10 um resolution)

- Semiautomatic polishing machine

Surface Characterization

- Scanning Electron microscopy (FEI eSEM Dual Beam™ Quanta 3D FEG), incl. EDX, environmental cell, temperature control

- Atomic Force Microscopy

- JPK Nanowizard, Electrochemical AFM, MFM, conductive-AFM, force-distance measurements

- Bruker Resolve, PeakForce Tapping, Electrochemical AFM, MFM, conductive-AFM, force-distance measurements

- Surface Plasmon-Resonance (Autolab Twingle, standard and EC cuvette)

- Optical microscopy (Zeiss, Axioscope, Bresser)

- Darkfield microscopy

- ATR-SEIRAS spectroelectrochemistry (Veemax III and Jackfish Cell)

- Microscopic FTIR in reflectance/transmission mode

Nanoparticle Characterization

- DLS and Zeta-potential measurements

- Malvern, Zetasizer Nano ZS

- Wyatt, DynaPro NanoStar

- UV-vis spectrometry

- Agilent Cary 60

- Eppendorf BioSpectrometer

- SEM & EDX (FEI, Quanta 3D FEG)

Nanoparticle Synthesis

- 5-port Schlenk lines

- vacuubrand VACUULAN System

- Plasma cleaner

Micro and nano electrode fabrication

- Laser puller (PL-2000 Sutter) for borosilicate and quartz nanopipettes preparation

- Crucible-heated microelectrode sealing (soda lime and borosilicate glass)

- Laser-assisted sealing of metal nanoelectrodes (platinum in quartz)

- Multi-electrode options starting from multi-barrel electrodes

Corrosion Studies

- Büchi Miniclave steel (100bar, 200°C)

- High pressure electrode fitting for the reactor